A Complete Guide to Investigating the Endless Possibilities of Laser Cutting

Explore the realm of laser cutting, a revolutionary technique that creates endless possibilities, and let your creativity run wild! If you’re interested in innovation, whether you’re an artist, designer, engineer, or simply have a passion for technology, laser cutting is a game-changer for precision manufacturing.

This cutting-edge method has completely changed industries thanks to its exact cuts and limitless versatility. Everything you need to know about laser cutting—from its definition and advantages to the various kinds of laser cutters now on the market—will be covered in this comprehensive guide. So buckle up as we travel on a thrilling adventure through the realms of laser-cutting brilliance!

How does laser cutting work?

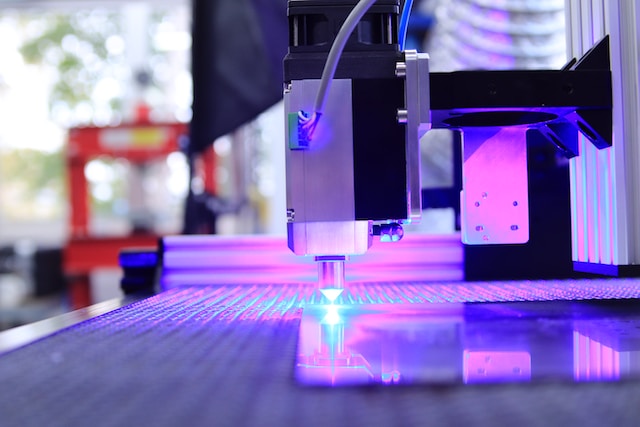

You may wonder what laser cutting is. Modern technology uses a laser beam that is extremely focused to precisely cut through a variety of materials. Laser cutting, as opposed to conventional techniques like sawing or drilling, delivers unmatched accuracy and complexity.

Laser cutting machine, a robust device with the ability to create an intense beam of coherent light, is at the centre of this procedure. The substance being cut is melted or vaporised by this concentrated energy, leaving behind clean edges and perfect finishes. Laser cutting can be used to create precise patterns on fragile materials as well as complicated designs on metal sheets.

The adaptability of laser cutting is one of its main benefits. A wide variety of materials, including wood, acrylic, plastic, metal, leather, paper, and even glass, can be used with ease. Its versatility makes it perfect for a wide range of applications in many industries, including jewellery design, automotive manufacture, and architectural modelling.

Additionally, laser cutting offers astounding speed and efficiency, cutting down on production time tremendously.

Additionally, there is little chance of the material itself being distorted or damaged because it is a non-contact technique.

As a result, whatever project you work on will be more productive and produce less waste.

Therefore, laser cutting brings up endless chances to bring your ideas to life with unsurpassed precision, whether you’re making unique signage, prototyping new products, or adding fine details to your artwork.

Exploring the potential of this amazing technology has no boundaries, in fact!

Gains from Laser Cutting

The use of laser cutting has completely changed the production and design industries, and it is now a necessary tool across a wide range of sectors. The accuracy of laser cutting is one of its main benefits. Every piece is cut precisely as planned because of the focused laser beams’ amazing accuracy in making delicate and detailed cuts.

The adaptability of laser cutting is another important advantage. Laser cutters can easily deal with a variety of materials, including wood, metal, plastic, and even fabric. The design and creative possibilities are virtually limitless because of this versatility.

Laser cutting also provides outstanding speed and efficiency. Contrary to conventional techniques like sawing or milling, lasers can produce precise cuts at rapid speeds without sacrificing quality. In addition to saving time, this boosts productivity and lowers the cost of production.

Furthermore, laser cutting offers straight edges free of distortion and burrs. Unlike conventional cutting techniques, which involve physically chipping or grinding away the material, the heat produced by the laser beam practically melts the material away. The resultant product has rounded edges and requires little post-processing.

Furthermore, laser cutting is a non-contact technique, which means that the machine and the material being cut are not in direct physical contact. By doing so, there is little chance that delicate materials will be harmed, and dealing with fragile goods is now more flexible.

One cannot ignore the benefits laser cutting technology has for the environment. When compared to more conventional techniques like plasma or waterjet cutting, this technology produces significantly less waste while using less energy and less harmful chemicals.

Precision cuts, adaptability to various materials, speed and efficiency, clean-cut edges, a non-contact technique, and environmental friendliness are just a few of the advantages of using laser cutting.

These benefits demonstrate why more industries are utilising this cutting-edge method to realise their ideas with unmatched accuracy and quality.

The Various Forms of Laser Cutters

There are many different kinds of laser cutters on the market for laser cutting. Each variety caters to various wants and requirements with its own special features and advantages. Let’s look at a few of the most common types:

- CO2 Laser Cutters: The laser beam is produced by these devices using a combination of carbon dioxide gas. They can cut through a variety of materials, including wood, acrylic, leather, and fabric.

- Fibre Laser Cutters: Fibre laser cutters employ optical fibres to enhance the laser beam and are renowned for their great precision and speed. They are perfect for cutting metals like copper, brass, aluminium, brass, and stainless steel.

- Laser cutters for neodymium (Nd) YAG: YAG lasers generate a strong beam that can pierce metals and ceramics using crystal rods constructed of yttrium aluminium garnet doped with neodymium.

- Diode laser cutters: These small, inexpensive devices are frequently utilised for DIY projects or other small-scale uses. They operate by producing a focused laser beam using diodes.

- Excimer laser cutters: Typically utilised in the fabrication of electronic or medical products, excimer lasers produce short-wavelength ultraviolet light ideal for precisely removing materials.

- Solid State Lasers: These lasers offer remarkable performance in terms of power output and longevity. Examples include Ruby lasers and Erbium-Ytterbium glass lasers.

Depending on the material you need to precisely cut or precisely engrave, each type has its own advantages! There is a laser cutter out there that is best suited for your unique needs, whether you’re searching for elaborate drawings on fabrics or accurate cuts on metal sheets!

However, always keep in mind that before making your final choice, you should take into account aspects like your available budget, the available space, the required maintenance, and the overall volume of production.