Optimizing Air Flow: The Essential Role of Air Valves in Various Applications

In the intricate web of systems that control the flow of fluids, air valves emerge as unsung heroes, quietly regulating air movement to ensure the efficient operation of various processes. From industrial applications to water distribution systems, air valves play a crucial role in maintaining equilibrium, preventing damage, and enhancing overall system performance. In this exploration, we delve into the multifaceted world of air valves, unravelling their importance, types, and diverse applications.

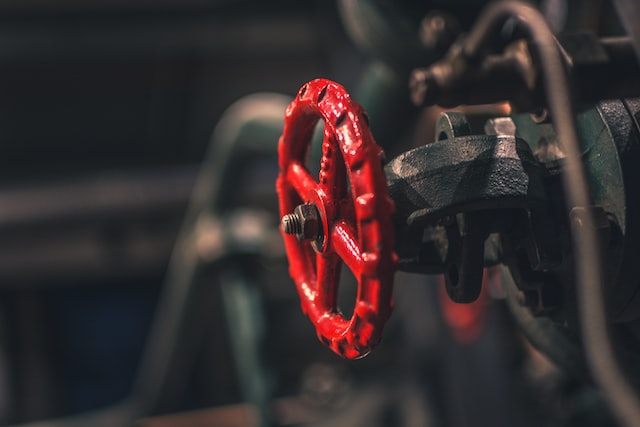

Air valves, in their simplest form, are devices designed to control the flow of air within pipelines or systems. While they might appear unassuming, their impact is far-reaching, influencing the efficiency and functionality of diverse applications. The primary purpose of airvalves.com.au is to manage the entry, release, or isolation of air within a system, preventing issues such as airlocks, cavitation, and damage to pipelines.Air valves come in various types, each tailored to specific functions within a system. One common type is the air release valve, designed to expel excess air from pipelines. This prevents the formation of air pockets, which can impede the flow of fluids. On the flip side, air vacuum valves perform the opposite function by allowing air to enter the system when needed, preventing the creation of a vacuum that could lead to pump damage. Combination air valves integrate both release and vacuum functions, providing a comprehensive solution to air control.

Airlocks, caused by trapped air in pipelines, can impede the flow of liquids and disrupt the operation of pumps and other machinery. Air release valves strategically placed along the pipeline help prevent airlocks by allowing trapped air to escape. Cavitation, another concern in fluid systems, occurs when air or vapour bubbles collapse, causing damage to equipment surfaces. Properly functioning air valves mitigate the risk of cavitation by regulating air levels and maintaining fluid flow.

Efficiency is a cornerstone of any well-designed system, and air valves contribute significantly to achieving and maintaining optimal efficiency. By ensuring a controlled and balanced air-to-fluid ratio, air valves facilitate smooth operation, reduce energy consumption, and extend the lifespan of pumps and other equipment. The proactive management of air within a system prevents unnecessary strain on components, resulting in improved overall efficiency.

In water distribution systems, air valves play a pivotal role in maintaining water quality and preventing issues such as pipe bursts. Air release valves allow entrapped air to escape, preventing its accumulation at high points in the pipeline. This not only ensures the uninterrupted flow of water but also safeguards against potential damage caused by air pressure fluctuations. In large-scale water distribution networks, the strategic placement of air valves becomes crucial for system resilience.

Wastewater treatment plants rely on complex systems to manage the flow of sewage and effluent. Air valves assist in this process by regulating air entry and release, preventing the formation of air pockets that could disrupt the movement of wastewater. Additionally, air vacuum valves contribute to maintaining optimal pressure levels within the system, preventing the ingress of air that could impede the efficiency of pumps and treatment processes.